Silica, Crystalline

Silica Sand

Construction

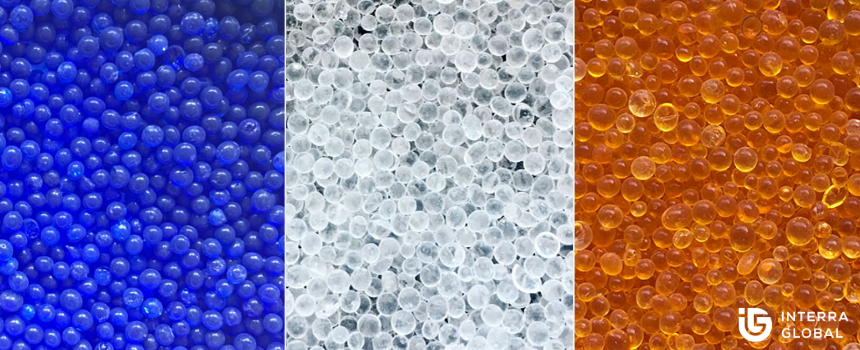

Silicon dioxide, commonly known as silica, is one of the most studied materials for the preparation of inorganic membranes. Although silica has several crystalline polymorphs, amorphous silica has been widely studied for the preparation of both mesoporous and microporous membranes. Silica was created to be the most sustainable alternative to vinyl. Silica Prints is an innovative addition to the Silica family of products. Silica Prints offer all the environmental, cleaning and performance benefits of Silica with endless design possibilities. Silica Prints, is a new paradigm for printed coated fabrics. Crystalline silica is a common mineral found in the earth's crust. Materials like sand, stone, concrete, and mortar contain crystalline silica. It is also used to make products such as glass, pottery, ceramics, bricks, and artificial stone.

What Is Silica

OSHA's Respirable Crystalline Silica standard for construction requires employers to limit worker exposures to respirable crystalline silica and to take other steps to protect workers.

The standard provides flexible alternatives, which OSHA expects will be especially useful for small employers. Employers can either use the control methods laid out in Table 1 of the construction standard, or they can measure workers' exposure to silica and independently decide which dust controls work best to limit exposures to the PEL in their workplaces.

Regardless of which exposure control method is used, all construction employers covered by the standard are required to:

- Establish and implement a written exposure control plan that identifies tasks that involve exposure and methods used to protect workers, including procedures to restrict access to work areas where high exposures may occur.

- Designate a competent person to implement the written exposure control plan.

- Restrict housekeeping practices that expose workers to silica where feasible alternatives are available.

- Offer medical exams-including chest X-rays and lung function tests-every three years for workers who are required by the standard to wear a respirator for 30 or more days per year.

- Train workers on work operations that result in silica exposure and ways to limit exposure.

- Keep records of exposure measurements, objective data, and medical exams.

Construction employers must comply with all requirements of the standard by September 23, 2017, except requirements for laboratory evaluation of exposure samples, which begin on June 23, 2018.

Construction Outreach Materials

Applying water to a saw blade when cutting materials that contain crystalline silica — such as stone, rock, concrete, brick, and block — substantially reduces the amount of dust created during these operations.

OSHA Small Entity Compliance Guide for Construction. Discusses suggested engineering and work practice controls, exposure assessments, respirator use, medical surveillance, written exposure control plans, and other aspects of compliance.

Sample Training Powerpoint for Construction. Provides a customizable Powerpoint for employers and other instructors to tailor their training on how to comply with OSHA’s respirable crystalline silica standard for construction.

OSHA's Crystalline Silica Rule: Construction. Revised Provides a summary of the requirements of the respirable crystalline silica standard for construction.

Controlling Silica Dust in Construction Fact Sheets for Table 1 Tasks

Controlling Silica Dust in Construction Videos for Table 1 Tasks

OSHA Standards, Interpretations, and Directives

Construction Industry (29 CFR 1926)

- 1926 Subpart Z, Toxic and Hazardous Substances

- 1926.1153. Respirable Crystalline Silica

- Appendix A, Methods of Sample Analysis

- Appendix B, Medical Surveillance Guidelines

- 1926.1153. Respirable Crystalline Silica

OSHA Directives

- NewInspection Procedures for the Respirable Crystalline Silica Standards

- Search all available directives.

Standard Interpretations

- Search all available standard interpretations.

Frequently Asked Questions

Silica Gel Packets

- Search all available frequently asked questions (FAQs) for the silica rule.

State Standards

There are twenty-eight OSHA-approved State Plans, operating state-wide occupational safety and health programs. State Plans are required to have standards and enforcement programs that are at least as effective as OSHA's and may have different or more stringent requirements.

Resources for the Construction Industry

Silica Water

- Silica. National Institute for Occupational Safety and Health (NIOSH) Safety and Health Topic. Provides information about silica as well as links to related publications and references.

- Control of Hazardous Dust during Tuckpointing. U.S. Department of Health and Human Services (DHHS), National Institute for Occupational Safety and Health (NIOSH) Publication No. 2008-126, (2008, September).

- Silicosis in Sandblasters: A Case Study Adapted for Use in U.S. High Schools. U.S. Department of Health and Human Services (DHHS), National Institute for Occupational Safety and Health (NIOSH) Publication No. 2002-105, (2002, June). Provides a case study developed for use in teaching epidemiology to high school students. Includes basic information about the disease silicosis, potential routes of exposure to silica, and controls.

- Working Safely with Silica. The Center for Construction Research and Training (also known as CPWR) has a website with resources to help contractors and workers understand the health risk involved and implement measures to control dust.

- Silica and Road Construction: Silicosis. New York Department of Health document addressing silica dangers in road construction.

- OSHA Clinicians page. The page provides information for clinicians to understand important ethical, regulatory, and clinical issues.

Silica Sand

Contractors adopt innovative concrete drill jig to reduce silica exposures during concrete drilling operations. Read more.

Related Safety and Health Topics Pages